MNS-21K Industrial Bacon Sausage Ham Frozen Meat Slicer

1. SUS 304 Material

2. Cut thickness is same

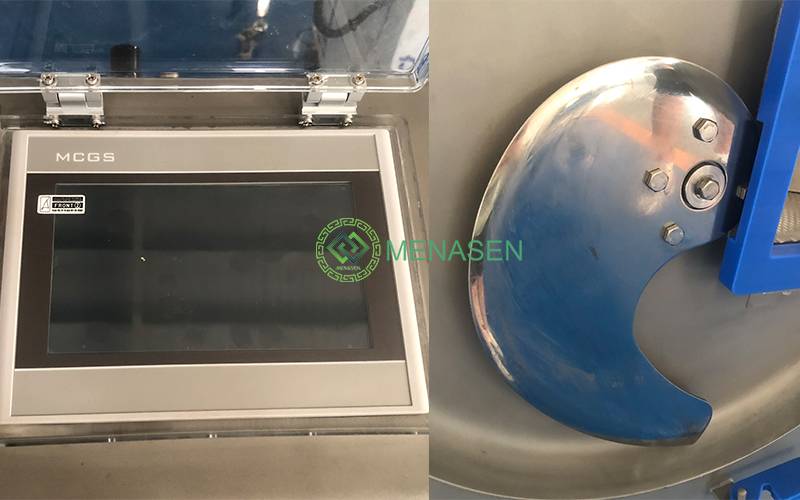

3. PLC operate panel

4. Voltage can be customize

5. Blade is import from Germany

6. Lead time is 15 dyas

1. SUS 304 Material

2. Cut thickness is same

3. PLC operate panel

4. Voltage can be customize

5. Blade is import from Germany

6. Lead time is 15 dyas

Industrial meat slicer can cut frozen ribs, cheese, bacon, ham, bacon, sausage, meat, fish, chicken steak, duck, etc. into slices. Slicer machine is convenient and quick to clean and the operation is simple and safe. It is a multifunctional meat cutting machine that integrates frozen meat slicing, chopping, segmentation. Adjustable cutting thickness. The thruster automatically returns to position, saving time and improving efficiency. Widely used , such as bacon, pork chops, pork belly, smoked pork, steak, beef, cheese, sausages, fresh or frozen meats, boneless and boneless products, etc. The equipment is suitable for use in large meat food factories, meat joint factories, slaughterhouse processing factories, and other places, especially in food processing factories that produce frozen meat.

Capacity: 155 pcs/min

Power: 3.55 Kw

Feeding width: 210 mm

Feeding height: 190 mm

Slice thickness: 1-32 mm (adjustable)

Voltage: 380V 3ph 50hz

Net weight: 600 KG

Gross weight: 690 kg

Machine size: 1950*1100*1500 mm

Packing size: 2150*1280*1750 mm

Capacity: 200 pcs/min

Power: 4.55 Kw

Feeding width: 250 mm

Feeding height: 210 mm

Slice thickness: 1-32 mm (adjustable)

Voltage: 380V 3ph 50HZ

Net Weight: 650 KG

Gross weight: 749 kg

Machine size: 2000*1200*1500 mm

Packing size: 2200*1350*1750 mm

1. Whole machine use stainless steel.

2. Good performance and stability.

3. Blade of slicing machine.

4. Operating Functions.

5. Touch screen, can change into English.

6. Slice Show.

1. Intelligent pneumatic cutting special claws prevent the product from slipping and ensure the quality of the product.

2. The intelligent surplus material throwing device achieves the largest income from the use of materials and accelerates the production speed.

3. The return limit is adopted, which saves time.

4. All important components, such as controller, PLC, reducer, and motor are imported to ensure product quality.

5. German cutting knife is sharp, durable and good in cutting quality.

6. The cutter is directly connected with the gear drive motor, which has high power usage efficiency and reliable safety measures.

7. Imported screw rod is used to drive the back paw, which is more accurate than belt transmission.